Clean Room

Cleanroom consignment management

Upcoming cleanroom performance evaluation,

It needs to be prepared with professional management.

As industrial technology becomes more highly integrated, human resources, environment, equipment, raw materials, utilities, etc. that are directly or indirectly involved in production

It is necessary to maintain optimal conditions to meet the appropriate standards. It is necessary to manage and control airborne particles.

Autonomous quality management for the clean room for the purpose of improving production yield and strengthening technological competitiveness,

External quality assurance is also guaranteed. Group quality certification by the Korea Air Cleaning Association.

With the implementation of the Cleanroom Performance Evaluation imminent, is your cleanroom environment being properly managed?

Service Procedure

- Performance Evaluation Process

-

Step 1

receipt

- Request for a third-party clean room company

- Request for performance evaluation of manufactured products

- Request for regular Clean Room evaluation

Step 2On-site verification

- Clean Room Detailed Location and Brief Map

- Clean Room Design Conditions

- Check out the product and review locations

Step 3Performance Evaluation

- Particle / Temperature and humidity / Differential pressure

- Addition of items upon customer request

Step 4Issuance of transcripts

- Preparation and issuance of test report upon acceptance

- Suggestions for environmental improvement points

Service items

- Cleanroom solutions and

Technical capabilities -

01

Optimizing the cleanroom environment

- Room environment measurement and patrol inspection

- Issue-related response

- On-site verification of abnormal occurrences

- Identifying root causes through 3D airflow analysis

C/R traversal verificationOnline MonitoringAMC ControlEnvironmental verification02Ensuring core equipment performance

- Equipment Internal FFU and Environmental Verification (T.A.B)

- Real-time environmental monitoring during equipment operation

- Ionizer / Precise evaluation of static electricity levels

Mini EnvironmentWafer exposure environment verificationPrevent ESD particle adsorptionP/Counter & S/Com03FMS

- Building and maintaining a stable FMS system

- Regular assessment of the reliability of measuring equipment

- Immediate emergency response when an FMS issue occurs

System ManagementReal-time analysisComprehensive Environmental AssessmentP/Counter & S/Com04Ionizer and static electricity management

- Controlling electrostatic contamination from an ESDA perspective

- Precise evaluation and improvement of ionizer performance

- Static Control and Testing

Ionizer Performance EvaluationPrevent ESD particle adsorptionRoom/Equipment Environment Assessment05Micropollution Assessment and Analysis

- Building and maintaining a stable FMS system

- Regular assessment of the reliability of measuring equipment

- Immediate emergency response when an FMS issue occurs

System ManagementReal-time analysisComprehensive Environmental AssessmentP/Counter & S/Com

- Detailed technical services

-

01

Clean room environment

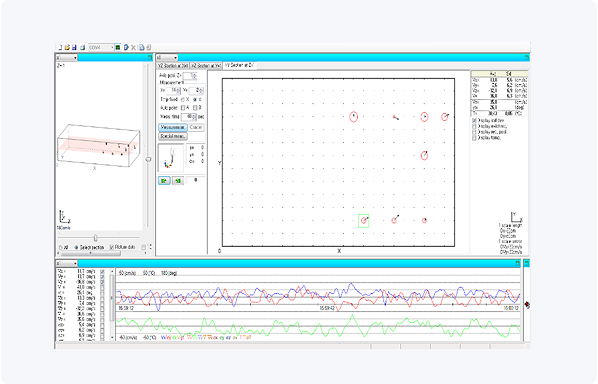

Online Monitoring

- Real-time analysis and system management

T.A.B

- Comprehensive Environmental Assessment

C/R traversal verification

- Environmental verification

02Equipment internal environment

Mini Environment

- Wafer exposure environment verification

- P/Counter & S/Com

Ionizer Performance Evaluation

- Prevent ESD particle adsorption

- Room / Equipment

03Utility Quality

DIW Quality

- Ultrapure water quality verification

- 18M DIW Monitoring

Chemical Metal Trend

- Metal concentration assessment

- DIW / H2O2 / NH4OH

04ECCB

Workmanship Audit

- Change point Control and workers, construction, etc.

Issue

Environmental assessment

- Change Area Environmental Pollution Assessment

- Technical capabilities

-

01

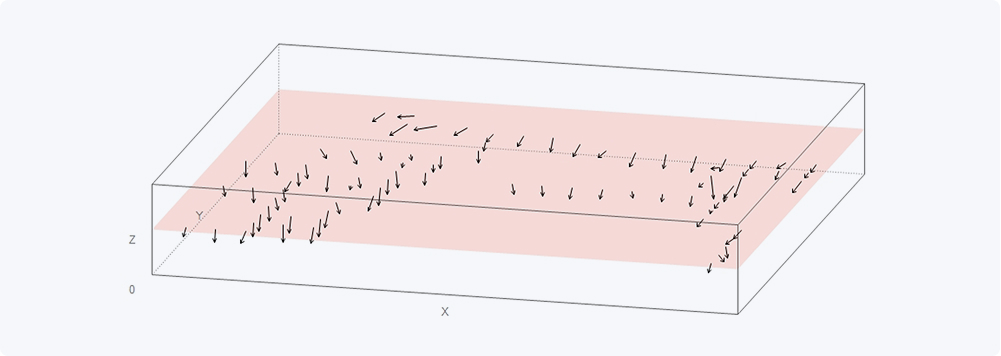

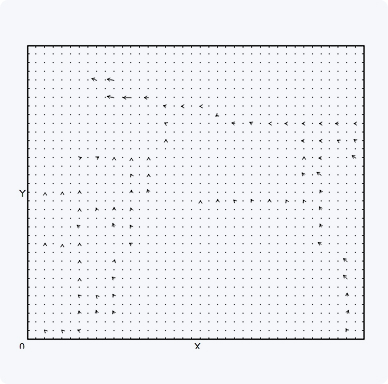

3D airflow analysis and CFD simulation

Prevent the spread of contaminants and maintain optimal air conditioning system efficiency by accurately identifying points where airflow stagnates or vortices occur within a cleanroom.

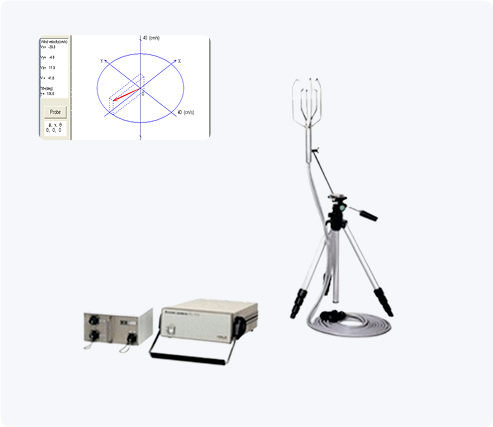

3D airflow analysis equipment

3D airflow analysis equipmentWith the most advanced 3D ultrasonic anemometer

Precisely measure the airflow on site. CFD simulation

CFD simulationThrough computational fluid dynamics (CFD) simulation

May occur when changing equipment layout or new construction

Predict and prepare for air current changes in advance.02Particle and air pollution component analysis

Beyond measuring pollution levels, we precisely analyze the components of pollutants to trace the source of pollution and suggest fundamental solutions.

- BIO GMP

-

Cleanliness grade ISO grade number floating bacteria parasitic bacteria Surface fungi (equipment) A 5 < 1 < 1 < 1 B 6 ≤ 10 ≤ 5 ≤ 5 C 7 ≤ 100 ≤ 50 ≤ 25 D 8 ≤ 200 ≤ 100 ≤ 50

- BIO Clean Room

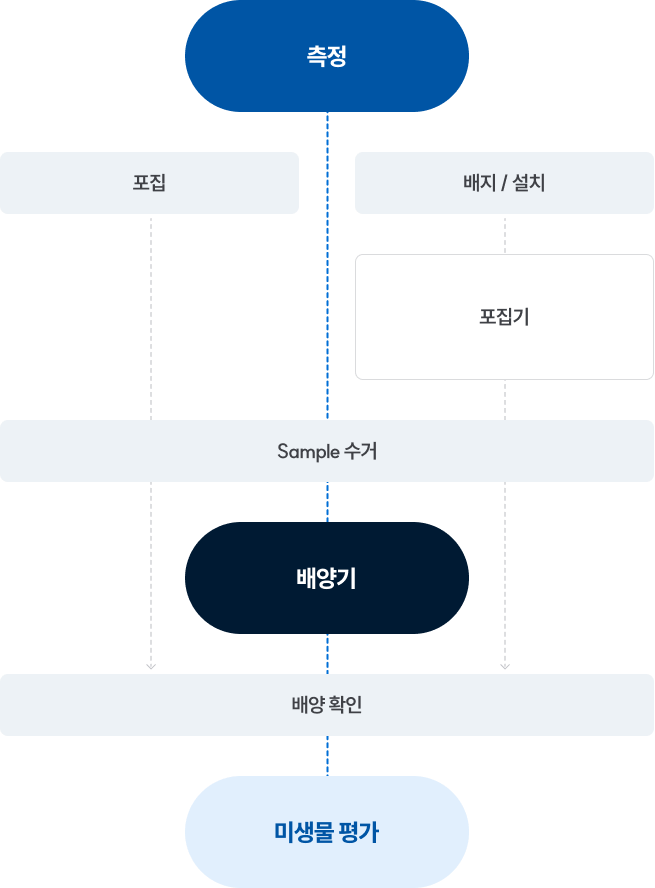

Microbiological evaluation -

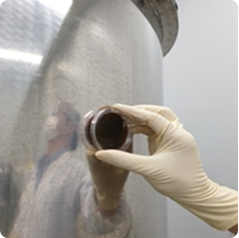

Key sampling and analysis items

- wealthy group

- Using a collector

- parasitic bacteria

- Neglect assessment

- Surface fungi

- Direct capture

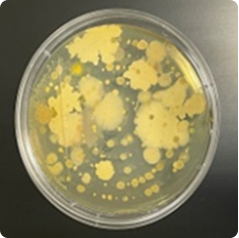

- incubator

- Microbial culture

- microorganism

evaluation - Visual confirmation