Test area

Environmental reliability

Equipped with cutting-edge facilities for vibration, shock, temperature and humidity, etc.

We provide environmental testing that complies with major international standards for defense and combat equipment.

Reliability means the ability of a part, product or system to operate under given conditions of use (operation) for a required period of time.

Reliability testing is the ability to maintain a designed function without failure (or the probability of operation). Reliability testing is designed to assess a product's lifespan or failure rate.

We offer environmental testing in compliance with major international standards for defense and electronic components, equipped with cutting-edge equipment for vibration, shock, temperature, and humidity. We support reliability verification through compliance with a wide range of standards, including MIL-STD, RTCA/DO, and IEC.

Testing Competency

- Test field target items

-

01

Information and communication devices

ITE

02battery

BATT

03military equipment

THOUSAND

04Battle equipment

Automotive

- Target device

-

Testing of product groups used in vehicles, including car audio, navigation, and black boxes.

Target product examples

car audioNavigationblack box

- Reliability testing field

-

01

Constant temperature and humidity test

02Complex vibration test

03Mechanical impact test

04Durability test

05Waterproof/dustproof test

06Thermal shock test

07Drop/impact test

08Power fluctuation test

09Salt spray test

10Altitude test

- Key testable specifications

-

International standards

- IEC 60068-2 Series

- ISO 16750 Series

- ISO 20653

- IEC 60529

- KS R 1034vvv

Complete vehicle specifications

- ES95400-10

- 36-00-802

- VW80000

- SES E001-04

- GMW3172

Test equipment

- electrical test equipment

-

Bidirectional Programmable Power Supply

- Power waveform simulation

- PBZ20-20: Holds 6 EA

- PBZ40-10: Holds 1 EA

IN TEST

- E-10 Short interruptions

- E-13 Pin interruption

- Surge, EFT Burst, Power fail, Load dump 등)

Bidirectional Programmable DC Power Supply (High Voltage)

- Output Voltage : 0 ~ 1500 V

- Output Current : -40 ~ 40 A

- Output Power : -18 ~ 18 Kw

- 6 EA

Bidirectional AC Power

- Output Voltage : 0 ~ 350 V

- Output Current : 90 A (RMS)

- Output Power : 15 kVA

- 6 EA

- Electrical/Insulating Properties

Test equipment -

Bidirectional Programmable DC Power Supply (High Voltage)

- Output Voltage : 0 ~ 1500 V

- Output Current : -40 ~ 40 A

- Output Power : -18 ~ 18 Kw

Super insulation tester (SM7120)

- Capable of voltage output of 2,000 V (setting resolution 0.1 V)

- Up to 2 X 1019Ω display

Temperature/humidity chamber

- (-70 ~180) °C

- (10 ~ 98) % R.H.

- 1100 X 1000 X 1000 mm (internal)

- Temperature rise rate: 4.7 °C/min

- Temperature drop rate: 4.1 °C/min

- Maximum load: 300 kg

IP water spray tester

- Room size: 7,000x5300x3600 mm

- IPX1,2,3,4,4K,5,6,6K,7,8, UL50, IPX9K according to ISO 20653, IEC 60529

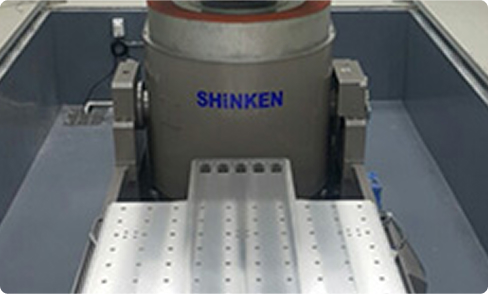

Composite vibration tester

- (3 ~ 2000) Hz

- Max acceleration : 100 g

- Table size: 1000 x 1000 mm

- Sine, Random, shock

- SOR, ROR

- Combination of composite chambers is possible

Composite corrosion tester

- 1460X820X460 mm

- emp spray mode : 60 °C

- Temp Dry-off mode: 70°C

- Ground mode temp: 60 °C

- Temp Dwell mode: 60 °C

Test Setup

[Electrical Performance Test – Power Supply]

Electrical Performance Tests – Environmental Conditions

[Electrical Performance Test – Power Pattern Simulation]

[Electrical Performance Test – Short/Pin interruptions]

[Electrical Performance Test – Withstand Voltage / Insulation Resistance]

[Electrical Performance Testing – ESD]

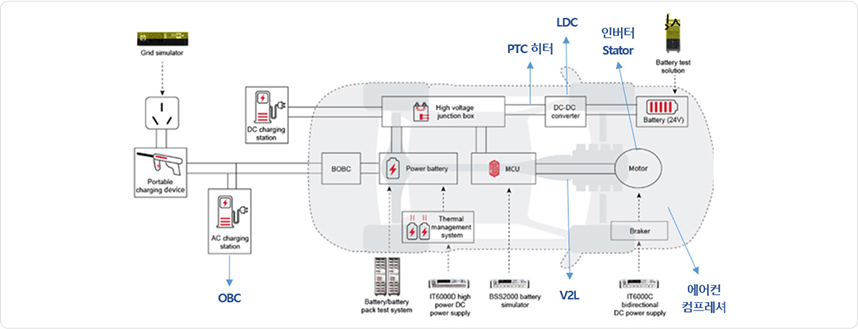

Introduction to EV Components/High-Voltage Testing

Environmental testing and electrical reliability testing of EV systems (PTC heater, LDC, OBC, Stator, V2L, slow charger, inverter, etc.) are possible.

AC Power/load: 15 kW class (6 EA), DC Power/load: 18 kW class (6 EA), chiller, etc. test utilities in stock

Electrical Performance Testing – High-Voltage Electrical Components

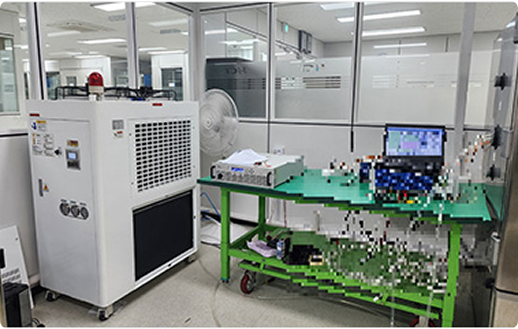

Introducing the EV Stator Durability Testing Facility

- Insulation durability

(Harsh environment durability)

Test equipment -

Large high temperature oven chamber

- 1,000(W) x 1,000(D) x 1,000(H) mm

- 25 ℃ ~ 280 ℃

Constant temperature and humidity chamber

- 1,100(W) x 1,000(D) x 1,000(H) mm

- -75 ℃ ~ 180 ℃, (10 ~ 98)%RH

Vibration tester

- 1,000(W) x 1,000(D) mm

- 3 Hz ~ 2 kHz

- Test Wave : Sine, Random, Shock

- Electrical/Insulating Properties

Test equipment -

Bidirectional Programmable Power Supply

- Insulation testing of motor windings for EVs and inverter drive motors

- Open output: 0.5 kVpeak ~ 5.0 kVpeak

- Count and display the number of spark discharges

- Calculate the number of corona discharges and display the percentage

ELECTRICAL SAFETY ANALYZER

- ACW((50~60)Hz, (0.5~5)kV,

(0.1~100)mA), DCW((0.5~7.2)kV, 10mA) - R((25~1000)V, 250MΩ~100GΩ))

Super insulation tester (SM7120)

- Capable of voltage output of 2000V (setting resolution 0.1V)

- Up to 20000PΩ display

Resistance meter (RM3544)

- 300 mA, 0.000 mΩ ~ 3.5 MΩ

- DC 300 mA ~ DC 500 mA

KC

KC  FCC

FCC  ISED

ISED  CE

CE  UKCA

UKCA  TELEC, JATE

TELEC, JATE